SiteAware

SiteAware is a digital construction verification platform that uses AI and 3D scanning to help construction teams ensure that their projects are built exactly as planned. It automatically identifies discrepancies between the building plans and the actual construction in real-time, allowing teams to correct errors before they become costly problems. This helps reduce rework, improve accuracy, and keep projects on schedule and within budget.

0

People watching this product now!

Key Information

| Discipline | , |

|---|---|

| Project Phase |

What is SiteAware used for?

SiteAware is a cloud-based platform that provides automated verification of construction elements as they are installed. This allows construction professionals to identify deviations from the plans in real-time, preventing costly rework and ensuring projects stay on schedule and within budget. The platform leverages digital twinning technology and artificial intelligence to compare the as-built condition with the original building plans, enabling proactive error prevention and improved quality control.

Key Features and Benefits

SiteAware offers a range of features designed to improve construction quality and efficiency:

- Real-time Verification: SiteAware verifies the accuracy of formwork, embeds, MEPF (mechanical, electrical, plumbing, and fire protection) installations, facade elements, and interior clearances during the construction process. This allows for immediate identification and correction of errors, minimizing rework and delays.

- Actionable Observations: The platform provides clear visual observations to all team members, highlighting deviations from the plans. These observations are "built for the field" and can even be used offline, ensuring that construction quality intelligence is readily available on site.

- Automated Scanning: SiteAware uses 3D scanning to capture detailed data on all structural elements and installations. This process works in the background, minimizing disruption to construction workflows.

- Digital Twinning: The platform automatically generates multi-layered as-builts, providing a virtual replica of the job site. This documentation is valuable for both construction management and future building operations.

- AI Verification: SiteAware utilizes AI to verify that each element is built according to plan. This enables the platform to provide real-time data, feedback, and actionable insights.

- Quality Management Platform: SiteAware's platform is built on a comprehensive data set derived from millions of construction elements across hundreds of projects. It utilizes AI to verify that each element is built according to plan, providing real-time data, feedback, and actionable insights to reveal patterns that help teams uncover errors, prioritize fixes, and make better decisions.

- Data Analytics: SiteAware provides data analytics that allow business executives to measure and compare performance and risk across their portfolio. This data-driven approach enables better decision-making and greater certainty in construction.

The benefits of using SiteAware include:

- Reduced Rework: By identifying and correcting errors in real-time, SiteAware significantly reduces costly and time-consuming rework.

- Improved Quality: The platform ensures that every element is installed according to plan, leading to higher quality construction.

- Increased Productivity: By streamlining quality control processes and preventing delays, SiteAware enhances overall construction productivity.

- Enhanced Collaboration: SiteAware facilitates better communication and collaboration among project teams by providing a centralized platform for accessing data and insights.

- Reduced Risk: By providing real-time visibility into potential issues, SiteAware helps mitigate construction risks and improve project predictability.

Error Prevention and Quality Control

SiteAware's core functionality centers around error prevention and quality control. By verifying the accuracy of construction elements in real-time, the platform allows for immediate identification and correction of deviations from the plans. This proactive approach minimizes the need for costly and time-consuming rework, ensuring that projects stay on schedule and within budget.

How SiteAware Works

SiteAware's Build-to-Plan™ platform streamlines the construction process through automated quality control, ensuring that you build as planned. The process begins with plan tagging, where SiteAware creates a common language for every element that needs to be installed. This allows the platform to connect to various CAD and BIM standards, regardless of the software or documentation used.

Next, automated 3D scanning captures detailed data on all structural elements, facade layers, and interior installations. This scanning process works in the background as you build, minimizing disruption to existing workflows.

The platform then uses this data to generate fast and accurate digital twins of the work performed. These digital twins are verified against the construction plans as the work progresses.

SiteAware utilizes artificial intelligence (AI) to verify that each element is built according to plan. This AI verification enables the platform to provide real-time data, feedback, and actionable insights, highlighting any deviations from the plans.

Finally, SiteAware collects a comprehensive data set from millions of construction elements across hundreds of projects. This rich data provides valuable insights into industry-wide metrics and trade performance, helping teams make better decisions and improve overall project outcomes.

The platform is built using Node.js for the server side, React for dynamic functionality, and MongoDB for data storage. It is hosted on AWS (Amazon Web Services), ensuring reliability and scalability.

Best Suited Projects

SiteAware is well-suited for a variety of construction projects, including:

- High-rise concrete buildings: SiteAware's real-time verification capabilities are particularly valuable in high-rise construction, where accuracy is crucial and rework can be extremely costly.

- Facade construction: The platform's continuous verification and documentation of facade workmanship helps prevent errors and eliminate punchlist compromises.

- Interior build-outs: SiteAware verifies interior clearances, layouts, and rough-ins before walls are closed, ensuring accuracy and preventing costly rework.

- Complex projects with multiple trades: SiteAware looks at the element level across trades, which allows it to measure the project in a way that takes into account the full complexity and intensity of construction as well as the accompanying need for accuracy. This makes it particularly beneficial for complex projects with multiple trades.

Relevant Disciplines

SiteAware is relevant to a range of disciplines within the construction industry, including:

- Construction Professionals: SiteAware provides valuable tools for general contractors, superintendents, project managers, and other construction professionals to manage quality control, track progress, and prevent rework.

- Software Engineers: SiteAware's platform utilizes advanced technologies such as AI and digital twinning, making it relevant to software engineers and those involved in developing and implementing construction technology solutions.

- Operations Teams: SiteAware's data analytics and reporting capabilities can be used by operations teams to monitor project performance, identify trends, and improve efficiency.

Relevant Project Phase

While SiteAware can be beneficial throughout the construction lifecycle, it is particularly relevant during the construction phase itself. By providing real-time verification and error prevention capabilities, SiteAware helps ensure that projects are built accurately and efficiently, minimizing the need for rework and delays.

Integrations

SiteAware integrates with several existing construction technologies, including:

- Autodesk BIM 360: SiteAware data can be seamlessly exported into Autodesk BIM 360, improving collaboration among project teams.

- Procore: The SiteAware application can be accessed directly within Procore, minimizing productivity losses due to task switching.

- PlanGrid: SiteAware data can be saved to PlanGrid documents, allowing easy referencing in drawings and RFIs.

Support and Training

SiteAware provides support and training resources to help users effectively implement and utilize the platform. Their implementation managers are experienced construction professionals who coach teams on incorporating data and intelligence from the platform into their workflows. Additionally, SiteAware offers online training classes and software customization to further support users.

Case Studies

SiteAware has been used on a variety of projects, demonstrating its effectiveness in reducing rework, improving quality, and enhancing productivity. Some notable case studies include:

- Granite Park VI: SiteAware provided digital field verification services for this 419,000-square-foot office building in Plano, Texas. The project, owned by Granite Properties, broke ground in late 2021. [Read more]

- ANDRES Construction Services: This leading Texas general contractor uses the SiteAware digital construction verification (DCV) platform to manage its quality control (QC) program across projects and do more with the same number of people. [Read more]

- Hines: This real estate development leader utilizes SiteAware's error prevention platform as an integral part of its accelerated approach to construction, ensuring projects are delivered on time and within budget. [Read more]

ROI and Key Metrics

While specific ROI data is not available, SiteAware's potential for reducing rework and improving productivity suggests a strong return on investment. Key metrics for measuring the ROI of SiteAware include:

- Reduction in rework costs: Track the cost of rework before and after implementing SiteAware to quantify the savings.

- Improvement in project schedule adherence: Measure the percentage of projects completed on time after using SiteAware.

- Increase in labor productivity: Monitor the number of units or elements installed per labor hour after implementing SiteAware.

- Reduction in punch list items: Track the number of punch list items identified after project completion.

Conclusion

SiteAware offers a compelling solution for construction professionals seeking to improve quality, reduce risk, and enhance productivity. Its real-time verification capabilities, combined with AI-powered insights and seamless integration with existing workflows, position it as a valuable tool for modern construction projects. By proactively identifying and correcting errors, SiteAware helps ensure that projects are built as planned, leading to greater certainty and improved outcomes for all stakeholders.

SiteAware's focus on quality assurance and error prevention sets it apart from many of its competitors. Unlike alternatives that primarily focus on progress tracking or project management, SiteAware prioritizes ensuring that every element is installed correctly the first time. This proactive approach to quality control can lead to significant cost savings, improved schedules, and enhanced project outcomes.

Furthermore, SiteAware's real-time verification capabilities provide immediate feedback to construction teams, allowing for faster error correction and preventing issues from compounding. This is a significant advantage compared to some alternatives that rely on periodic inspections or delayed feedback.

By seamlessly integrating with existing construction technologies and workflows, SiteAware minimizes disruption to established processes. This allows teams to easily adopt the platform and incorporate its data and insights into their daily operations.

Overall, SiteAware is a valuable tool for construction professionals looking to embrace digital transformation and improve their quality control processes. Its unique combination of real-time verification, AI-powered insights, and seamless integration with existing workflows positions it as a leader in the digital construction verification space.

Alternative Products

Matterport

Matterport creates digital twins** of real-world spaces. Imagine a 3D replica of a building or room, complete with immersive virtual tours and detailed measurements. This technology benefits various industries, especially real estate**, where potential buyers can virtually explore properties, and architecture**, where professionals can collaborate on designs in a 3D environment. Matterport uses 3D capture technology** and offers features like spatial data analysis**, making it a valuable tool for anyone who needs to digitize and understand physical spaces**.

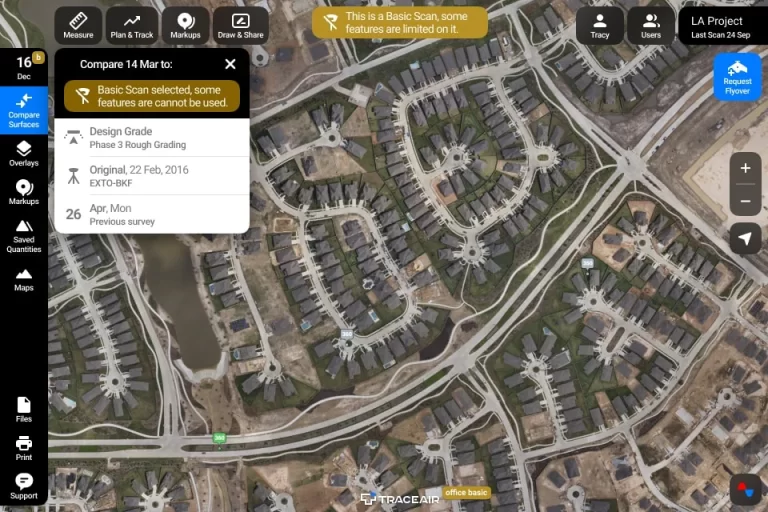

TraceAir

TraceAir is a construction site analysis and management platform that leverages drone data to simplify workflows and enhance project efficiency. The platform enables drone surveys to create accurate 3D topographical models of the site. Users can then overlay design documentation to compare as-built conditions with the intended design, track earthwork progress using cut/fill calculations, visualize stockpiles, manage site logistics, and collaborate easily with project stakeholders, all from a centralized web-based platform.

Canvas

Canvas is a service that creates "editable, layered as-built models" for remodelers, architects, interior designers, and construction professionals.

It uses reality capture technologies to document existing conditions and then integrates that data with design models (BIM).

Essentially, Canvas drafts digital models of existing buildings, which can then be used for renovations, redesigns, or other construction projects.

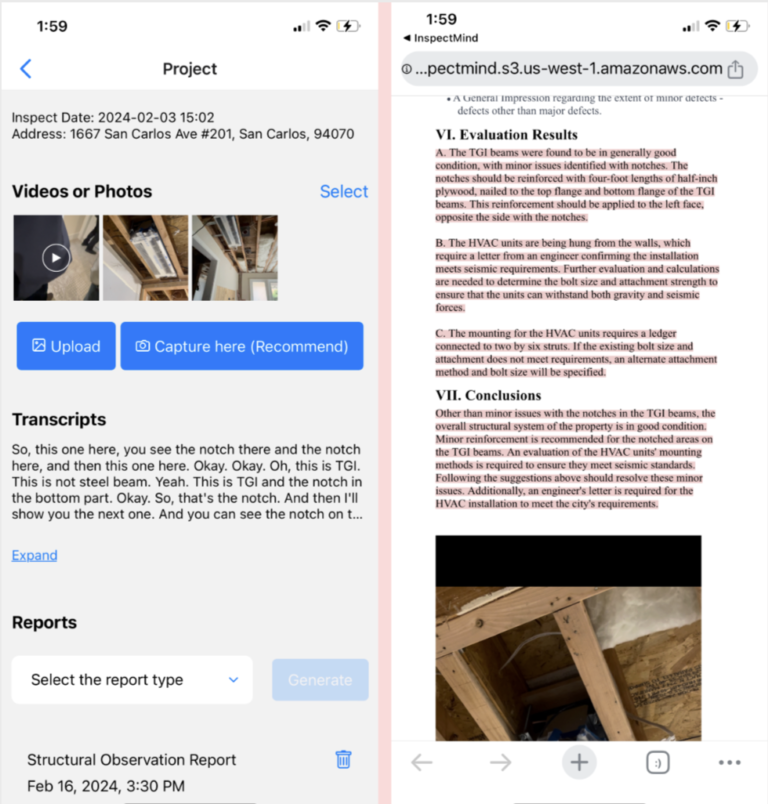

Inspect Mind

InspectMind is a software platform designed for the construction industry that utilizes artificial intelligence and computer vision to streamline the inspection process. It helps by automatically transforming voice recordings and photos captured on-site into detailed, accurate inspection reports, saving time and boosting overall workflow efficiency.

Vercator

Vercator is a cloud platform to quickly process your point cloud data.

Vercator’s registration service automatically aligns point cloud data without artificial scan targets. Powerful, fast and interoperable, register large, complex point cloud data with minimal intervention, saving you valuable time and resources.

Vercator classification extracts automated insight from point cloud data by separating data into different classes of interest and individual instances. This allows insight into assets in your scene allowing for quick understanding and data extraction for downstream modelling